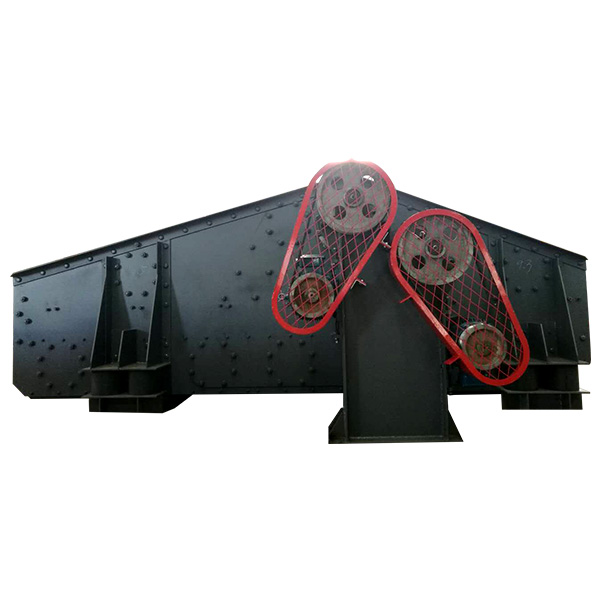

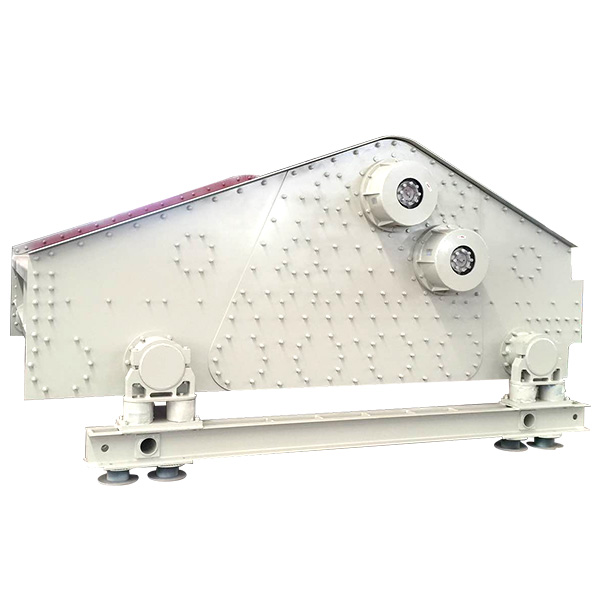

Factory Price Vibrating Screen Sieve Panels - ZSK linear vibrating dewatering screen – Jinte

Product introduction:

ZSK linear vibrating screen is linear movement and dewatering screen. Coal processing, mineral processing, power generation, sugar, salt and other industrial sectors can use this screening machine. ZSK linear vibrating screen is used for dry and wet screening, de-watering, dis-intermediation and de-silting of medium and fine materials.

Features & Advantages:

1. Small size, light weight, simple structure, convenient installation and easy maintenance;

2. Low noise, low energy consumption, high efficiency and low cost;

3. High screening accuracy, no dust pollution, conducive to environmental protection;

4. Can be replaced with a variety of screens, long service life;

5. Adopt block eccentric self-synchronous vibration exciter;

6. Vibrating screen can be used in other occasions with inclination.

Applications:

√ fine particle dewatering and grading

√ Recovering slime and tailings.

Working principle and structural features:

The vibro screen with flange type vibration exciter, from the two motor extension to reverse self-synchronous rotation, make the screen body along the straight line to do periodic reciprocating motion, so as to achieve the purpose of classification dehydration. The screen frame is connected by high-strength bolts, and the screen surface is composed of arc section and straight section. The structure is firm and durable.

Wanna see the delivery site, please click: https://www.hnjinte.com/news/vibrating-screen-has-been-shipped

Use and Maintenance:

A. starting sequence of dewatering screen: start in the direction of reverse material flow and stop in the direction of forward material flow. Avoid starting with materials, and stop after all materials are screened on the screen.

B. During the working process of the sieve, attention shall be paid to whether the operation of the sieve box is smooth or not.

C. The dewatering screen is generally installed with negative inclination Angle.

D. dust and impurities are easy to accumulate between springs, which will affect the normal operation of springs, and should be cleaned frequently.

E. often check the screen machine bolt connection, if there is a loose timely tightening.

F. The shaker bearing is lubricated with no. 3 lithium grease. Under normal conditions, lubricating oil should be added once a month and the bearing should be cleaned and inspected once a year.

|

No |

Name |

Unit |

ZSK-1231 |

ZSK-1431 |

ZSK-1837 |

ZSK-2448 |

ZSK-3645 |

|

|

1 |

Feed concentration |

% |

≥45 |

≥45 |

≥45 |

≥45 |

|

|

|

2 |

Processing capacity |

t/h |

15-19 |

15-19 |

28-33 |

60-120 |

>150 |

|

|

3 |

Screen size |

mm |

1200*3100 |

1400*3100 |

1800*3700 |

2400*4800 |

3600*4500 |

|

|

4 |

Screen size |

mm |

0.3,0.35 |

0.3,0.35 |

0.3,0.35 |

0.3,0.35 |

0.35 |

|

|

5 |

Double amplitude |

mm |

3-5 |

3-5 |

3-5 |

3-5 |

6-8 |

|

|

6 |

Vibration frequency |

Hz |

25 |

25 |

25 |

25 |

16 |

|

|

7 |

motor |

model |

Kw |

Y122M-4 |

Y132S-4 |

Y132M-4 |

Y180M-4 |

YE2-200L2-6 |

|

power |

||||||||

|

Voltage |

||||||||

|

8 |

V |

380 |

380 |

380 |

380 |

380 |

||

|

9 |

Single point maximum dynamic load |

N |

±200 |

±2500 |

±3500 |

±5000 |

52500 |

|

Factory Price Vibrating Screen Sieve Panels - ZSK linear vibrating dewatering screen – Jinte Related Video: