Reasonable price Gold Trommel Screen - JFSS series sintering environmental protection screen – Jinte

Introduction:

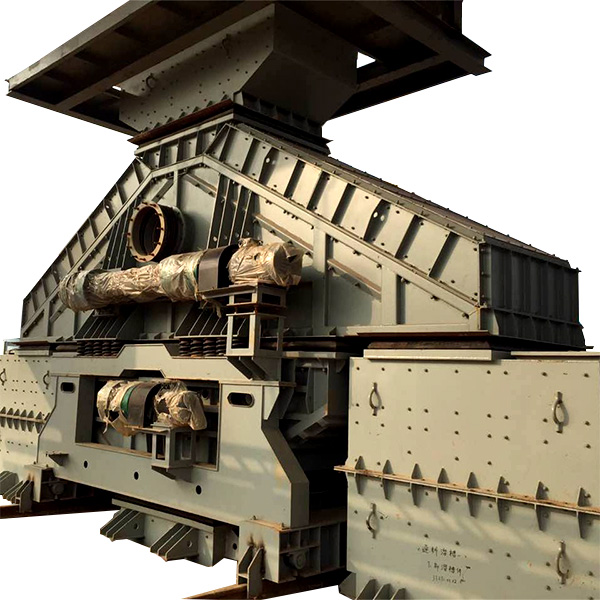

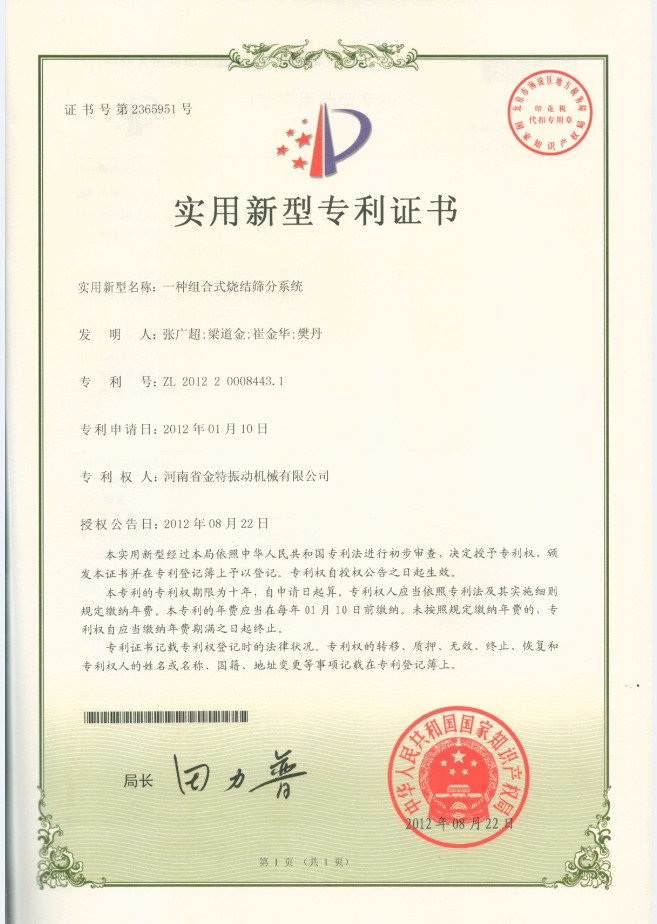

JFSS series new composite vibration screen is a new type of energy-saving composite vibration equipment independently developed by our company, which was granted the national patent in 2009. The screen machine is mainly used in blast furnace trough, sintering plant, raw material plant, coal, mining plant, ect.

Construction:

1. screen plate

2. feed port

3. material export on the screen

4. material export under the screen

5. screen box

6. sealing cover

7. dust removal port

8. vibration damping device

9. vibration source.

Features & advantages:

1. Be arranged back-to-back in the sieve box, with adult font arrangement and compact structure,which can effectively reduce the floor space and make reasonable use of space

2. Adopt rod and bar structure and be designed with self-cleaning device. High opening rate of sieve hole, not easy to block, high screening efficiency;

3. A sealing cover above the sieve box to make the screening work in a fully sealed state, which can effectively prevent dust generated by the screening from flying everywhere;

4. Equipped with dust removal port, which can absorb the dust generated in the work of the vibrating screen, greatly reduce the dust caused by screening materials, and improve the dust removal effect.

5. The sluice gate is designed at the feed inlet, which can effectively control the material flow, adjust the material flow amount on both sides of the screen plate, and make the material distribution balance.

6. The screen box can be supported on a fixed base, or on a walking bottom frame with walking wheel and rail clamp.

Technical Parameters:

|

JFSS Series Sintered Environmental Protection Screen |

|||||

|

Sintering Machine (㎡) |

Matched Vibrating Screen (Model) |

Processing Capacity (t/h) |

Quantity (Set) |

Blanking Granularity (mm ) |

Remarks |

|

|

|

|

|

|

|

|

90 |

JFSS105*600 Sintering Primary Sieve |

400 |

2 |

10 |

Open One, Get One Ready |

|

JFSS105*600 |

220 |

2 |

5 |

Open One, Get One Ready |

|

|

JFSS105*600 Sintering Tertiary Sieve |

220 |

2 |

20 |

Open One, Get One Ready |

|

|

180 |

2JFSS125*700-II Sintering Primary And Secondary Sieves |

500 |

2 |

20、10 |

Open One, Get One Ready |

|

JFSS125*600-I丨Sintering Tertiary Sieve |

300 |

2 |

5 |

Open One, Get One Ready |

|

|

2*180 |

2JFSS125*600-IV Sintering Primary And Secondary Sieves |

650 |

3 |

20、10 |

Open One, Get One Ready |

|

2JFSS125*600-IV Sintering Secondary Sieve |

400 |

3 |

5 |

Open One, Get One Ready |

|

|

265 |

2JFSS150*700-II Sintering Primary And Secondary Sieves |

700 |

2 |

20、10 |

Open One, Get One Ready |

|

JFSS150X600-I丨Sintering Secondary Sieve |

350 |

2 |

5 |

Open One, Get One Ready |

|

|

2*265 |

2JFSS150*700-IV Sintering Primary And Secondary Sieves |

750 |

3 |

20、10 |

Open One, Get One Ready |

|

2JFSS150*600-IV Sintering Secondary Sieve |

350 |

3 |

5 |

Open One, Get One Ready |

|

|

360 |

2JFSS150*700-MSintering Primary And Secondary Sieves |

890 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS150*600-I丨Sintering Secondary Sieve |

500 |

2 |

5 |

Open One, Get One Ready |

|

|

2*360 |

2JFSS150*700-IV Sintering Primary And Secondary Sieves |

950 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS150*600-IV Sintering Secondary Sieve |

700 |

2 |

5 |

Open One, Get One Ready |

|

|

450 |

2JFSS185*700-II Sintering Primary And Secondary Sieves |

1050 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS185*600-M Sintering Secondary Sieve |

700 |

2 |

5 |

Open One, Get One Ready |

|

|

2*450 |

2JFSS185*700-IV Sintering Primary And Secondary Ssieves |

1050 |

4 |

20、10 |

Open Three And Prepare One |

|

2 J FSS185*600- IV Sintering Secondary Sieve |

700 |

4 |

5 |

Open Two And Prepare One |

|

|

500 |

2JFSS200*700-II Sintering Primary And Secondary Sieves |

1150 |

2 |

20、10 |

Open One, Get One Ready |

|

2JFSS200*600-I丨Sintering Secondary Sieve |

800 |

2 |

5 |

Open One, Get One Ready |

|

|

2*500 |

2JFSS200*700-IVSintering Primary And Secondary Sieves |

1050 |

4 |

20、10 |

Open Three And Prepare One |

|

2JFSS200*600-IV Sintering Secondary Sieve |

700 |

4 |

5 |

Open three and prepare One |

|

Reasonable price Gold Trommel Screen - JFSS series sintering environmental protection screen – Jinte Related Video: