Competitive Price for Newly Designed Screens Vibrator Ultrasonic Vibrating Screening Sieve Machine

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for Competitive Price for Newly Designed Screens Vibrator Ultrasonic Vibrating Screening Sieve Machine, Now we now have established steady and lengthy company associations with clients from North America, Western Europe, Africa, South America, extra than 60 countries and regions.

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for Rotary Vibrating Screen, Ultrasonic Vibrating Screening Sieve Machine, Vibrating Screen Machine, because of our company has been persisting in the management idea of “Survival by Quality, Development by Service, Benefit by Reputation” . We fully realize the good credit standing, the high quality goods, the reasonable price and the skilled services are the reason that the customers choose us to be their long-term business partner.

High-precision Rotary Vibrating Screen

Introduction:

XZS series rotary vibrating screen is a new type of high efficiency screening machine for fine particle. It can carry out all kinds of fine powder, micro powder and ultrafine powder operation.

Rotary screen is a general vibro screen and dewatering screen. It has good application in powder, small particle and liquid materials.

The basic principle is to use the heavy hammer (unbalanced heavy hammer) installed above and below the motor shaft to transform the rotating motion of the motor into three dimension (horizontal, vertical and inclined motion) and then transfer this movement to the screen surface, so that the material on the screen surface is to do outside expansion movement, so this series of vibrating screen is called rotary vibrating screen.

Features & Advantages

Application industries

Tips for users to purchase

Technical Parameter

Tips for users to purchase

1. To meet the requirements and characteristics of individual industries, there are various types of design, such as: airtight/flanged/gated/direct discharge/water spray design or mobile conversion, etc.

2. The rotary vibrating screen material is made of general steel, stainless steel and carbon steel. General type of rotary screen products are made of general steel and stainless steel, mostly used for fine powder, powder, and dry and wet material screening.

Technical Parameter

|

Model Nominal diameter |

Model Nominal diameter |

Model Nominal diameter |

Model Nominal diameter |

Model Nominal diameter |

Model Nominal diameter |

Model Nominal diameter |

Model Nominal diameter |

Model Nominal diameter |

|

XZ-400 |

400 |

320 |

0.0804 |

<10 |

2-325 |

1-3 |

1500 |

0.25 |

|

XZ-600 |

600 |

550 |

0.2124 |

<10 |

1500 |

0.4 |

||

|

XZ-800 |

800 |

750 |

0.4072 |

<20 |

1500 |

0.75 |

||

|

XZ-1000 |

1000 |

950 |

0.6221 |

<20 |

1500 |

1.0 |

||

|

XZ-1200 |

1200 |

1150 |

0.9331 |

<20 |

1500 |

1.5 |

||

|

XZ-1500 |

1500 |

1450 |

1.5175 |

<20 |

1500 |

2.2 |

||

|

XZ-1800 |

1800 |

1720 |

2.322 |

<30 |

1500 |

3.7 |

||

|

XZ-2000 |

2000 |

1910 |

2.86 |

<30 |

1500 |

3.7 |

Factory & Team

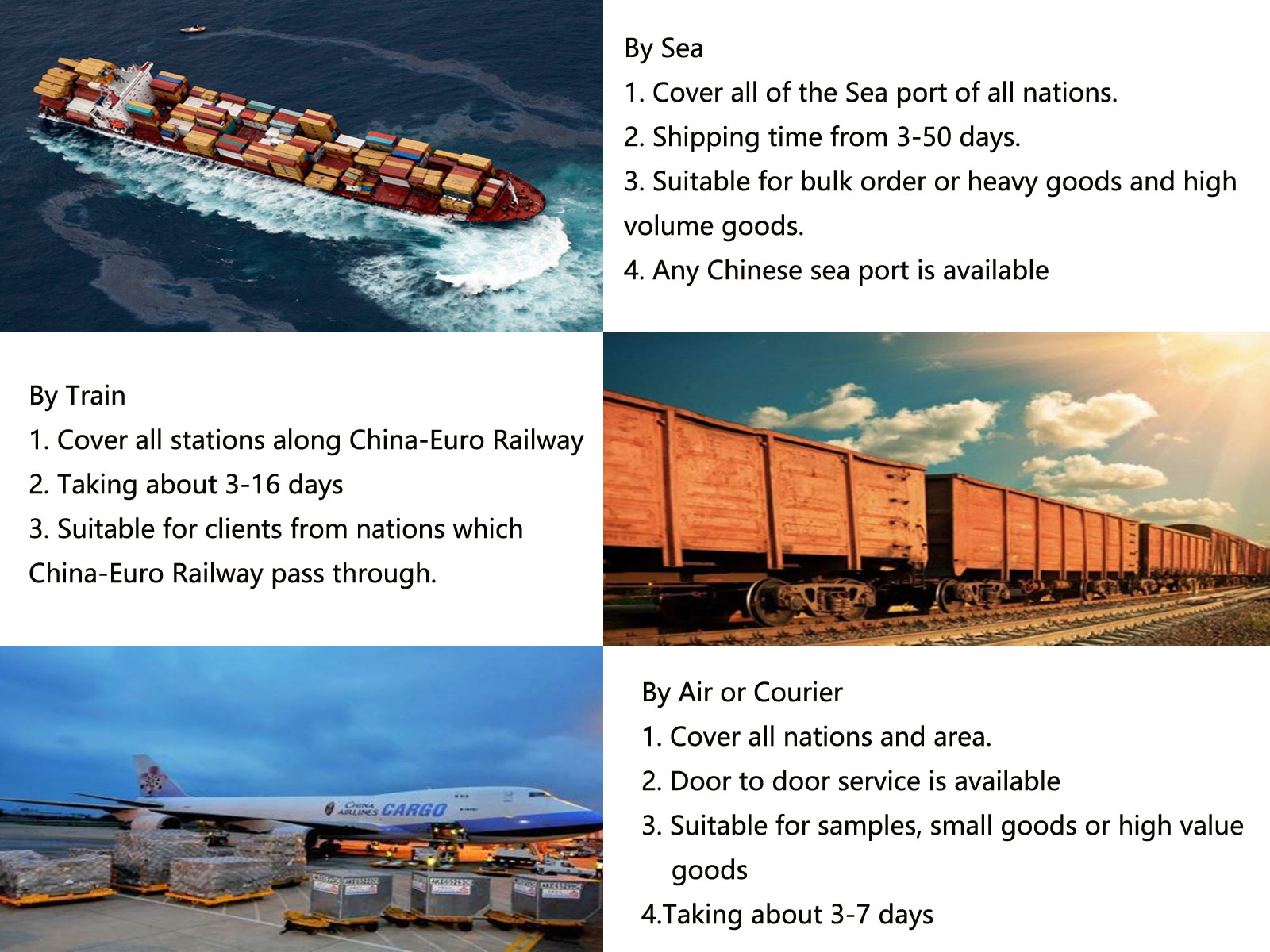

Delivery

Competitive Price for Newly Designed Screens Vibrator Ultrasonic Vibrating Screening Sieve Machine Related Video: