Factory directly supply Circular Vibrating Screener - High Quality for Vibrating Screen Various Dewater Screen – Jinte

Company Purpose:

With our advanced technology also as our spirit of innovation,mutual cooperation, benefits and advancement, we’ll build a prosperous future together with your esteemed organization for High Quality for Vibrating Screen Various Dewater Screen, Standing still today and looking into the future, we sincerely welcome customers all over the world to cooperate with us.

Insisting over the high-quality generation line management and prospects guide provider, we’ve made our resolution to offer our shoppers using the initially stage purchasing and soon after provider working experience. Preserving the prevailing helpful relations with our prospects, we even now innovate our product lists the many time to meet up with the brand new wants and stick to the latest trend of this business in Ahmedabad. We’re ready to facial area the difficulties and make the transform to grasp many of the possibilities in international trade.

Introduction:

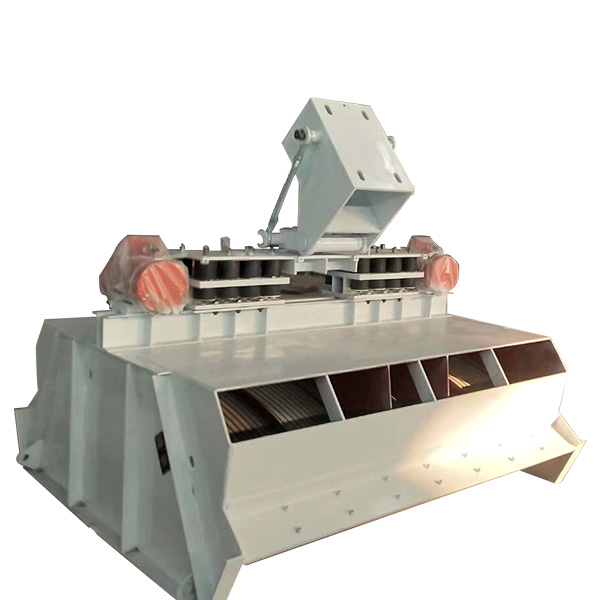

FHS arc screen is mainly used for pre-dewatering, desilting, disintermediation and grading recovery of coal slurry in coal preparation plant and ore dressing plant. Slurry realizes solid-liquid separation under the action of centrifugal force. The slurry can remove 60%-70% of the water in advance through the arc screen surface to ensure enough water spraying on the linear vibrating screen to clean the fine mud and medium adhered to the coal particles, which plays a key role in reducing product ash content and medium consumption.

FHS arc screen is made up of three parts: screen box, arc screen plate and base. The screen box adopts pivot steering structure, which can rotate 180°, and can be used in the process of using, it can not only extend the service life of stainless steel screen plate, but also improve the effect of dewatering, desilting and disintermedium.

Features & Advantages:

1. The curved screen surface and the screen frame adopt the pivotal special structure, which can rotate 180 degrees and extend the service life of the screen surface.

|

Model |

Screen Width (mm) |

Processing Capacity |

Sieve Pore(mm) |

Radius (mm) |

Wrap Angle(°) |

Screen Strip Width (mm) |

Weight(Kg) |

|

(m³/h) |

|||||||

|

FHS-09201 |

920 |

50-110 |

0.4-1.0 |

1016 |

45 |

2.38 |

750 |

|

FHS-1220I |

1220 |

70-145 |

0.4-1.0 |

1016 |

45 |

2.38 |

880 |

|

FHS-15201 |

1520 |

85-180 |

0.4-1.0 |

1016 |

45 |

2.38 |

1090 |

|

FHS-1820I |

1820 |

105-216 |

0.4-1.0 |

1016 |

45 |

2.38 |

1200 |

|

FHS-2120I |

2120 |

122-250 |

0.4-1.0 |

1016 |

45 |

2.38 |

1320 |

|

FHS-2420I |

2420 |

140-285 |

0.4-1.0 |

1016 |

45 |

2.38 |

1450 |

|

FHS-3000I |

3000 |

175-355 |

0.4-1.0 |

1016 |

45 |

2.38 |

1780 |

|

FHS-3200I |

3200 |

190-375 |

0.4-1.0 |

1016 |

45 |

2.38 |

1920 |

|

FHS-0920 II |

920 |

70-140 |

0.4-1.0 |

1016 |

60 |

2.38 |

850 |

|

FHS-1220 II |

1220 |

95-190 |

0.4-1.0 |

1016 |

60 |

2.38 |

1000 |

|

FHS-1520 II |

1520 |

119-240 |

0.4-1.0 |

1016 |

60 |

2.38 |

1120 |

|

FHS-1820 II |

1820 |

143-288 |

0.4-1.0 |

1016 |

60 |

2.38 |

1300 |

|

FHS-2120 II |

2120 |

167-336 |

0.4-1.0 |

1016 |

60 |

2.38 |

1400 |

|

FHS-2420 II |

2420 |

191-336 |

0.4-1.0 |

1016 |

60 |

2.38 |

1520 |

|

FHS-3000 II |

3000 |

240-430 |

0.4-1.0 |

1016 |

60 |

2.38 |

1900 |

|

FHS-3200 II |

3200 |

280-460 |

0.4-1.0 |

1016 |

60 |

2.38 |

2120 |

|

FHS-0920 III |

920 |

85-180 |

0.4-1.0 |

2032 |

45 |

2.38 |

950 |

|

FHS-1220 III |

1220 |

115-240 |

0.4-1.0 |

2032 |

45 |

2.38 |

1120 |

|

FHS-1520 III |

1520 |

145-300 |

0.4-1.0 |

2032 |

45 |

2.38 |

1230 |

|

FHS-1820 III |

1820 |

175-360 |

0.4-1.0 |

2032 |

45 |

2.38 |

1430 |

|

FHS-2120 III |

2120 |

205-420 |

0.4-1.0 |

2032 |

45 |

2.38 |

1530 |

|

FHS-2420 III |

2420 |

235-480 |

0.4-1.0 |

2032 |

45 |

2.38 |

1650 |

|

FHS-3000 III |

3000 |

295-600 |

0.4-1.0 |

2032 |

45 |

2.38 |

2050 |

|

FHS-3200 III |

3200 |

330-650 |

0.4-1.0 |

2032 |

45 |

2.38 |

2240 |

|

FHS-0920 IV |

920 |

115-240 |

0.4-1.0 |

2032 |

60 |

2.38 |

1050 |

|

FHS-1220 IV |

1220 |

156-320 |

0.4-1.0 |

2032 |

60 |

2.38 |

1120 |

|

FHS-1520 IV |

1520 |

195-400 |

0.4-1.0 |

2032 |

60 |

2.38 |

1310 |

|

FHS-1820 IV |

1820 |

234-480 |

0.4-1.0 |

2032 |

60 |

2.38 |

1500 |

|

FHS-2120 IV |

2120 |

272-560 |

0.4-1.0 |

2032 |

60 |

2.38 |

1640 |

|

FHS-2420 IV |

2420 |

312-560 |

0.4-1.0 |

2032 |

60 |

2.38 |

1780 |

|

FHS-3000 IV |

3000 |

392-720 |

0.4-1.0 |

2032 |

60 |

2.38 |

2150 |

|

FHS-3200 IV |

3200 |

430-800 |

0.4-1.0 |

2032 |

60 |

2.38 |

2350 |

Factory directly supply Circular Vibrating Screener - High Quality for Vibrating Screen Various Dewater Screen – Jinte Related Video: