Leading Manufacturer for Mining Vibrating Screen - K type reciprocating feeder (coal feeder) – Jinte

Introduction:

K-type reciprocating feeder (coal feeder) is to use the crank-connecting rod mechanism to drag the bottom plate down 5° to do straight reciprocating movement on the roller, so as to discharge coal or other loose granular, powder materials from the feeding equipment to the receiving equipment uniformly.

It can transfer bulk materials through the silos or directly to the rubber belt conveyor or other screening equipment, storage devices, etc. Uniform feeding of bulk materials such as ore, sand coal and grain is realized.

The machine block is installed under the hopper, and the transmission device is suspended, which can be divided into several types according to the size of feeding quantity: K1, K2, K3, K4 and so on.

Applications:

√ mines industry

√ mines industry

√ coal preparation plants

√ transfer stations

√ coal conveying workshops

√ port bulk materials wharfs

Features & Advantages:

1. Reliable operation, long service life, light weight, small size, convenient adjustment and installation.

2. The use of closed frame structure greatly improve the stiffness of the rack.

3. Equipped with limited torque hydraulic coupling, which can start with full load, and overload protection.

4. The maximum feeding capacity can reach 1200 tons/hour (coal), which is the larger reciprocating feeder in China at present.

5. Adopt advanced design of plane secondary enveloping ring mule rod reducer, with large bearing capacity and high transmission efficiency.

6. The seam can be adjusted between the side lining board, the inclined lining board and the bottom plate, which can control the seam size accurately and greatly reduce the leakage.

7. The drive device is arranged symmetrically, and the double push rod is adopted to balance the force on the whole machine, to make the transmission smooth and eliminate the torsion swing phenomenon when the bottom plate reciprocates.

8. The bottom plate has vertical rib plate and is supported by three-way long roller, which guarantees the rigidity of the bottom plate and eliminates the defects of bending deformation in the work of the current reciprocating feeder bottom plate.

9. The lining plate is composed of small pieces of wear-resistant steel plate, which is not only light and easy to replace, but also can be targeted to replace the worn lining plate according to the actual wear conditions, so as to make reasonable use of materials and reduce maintenance costs.

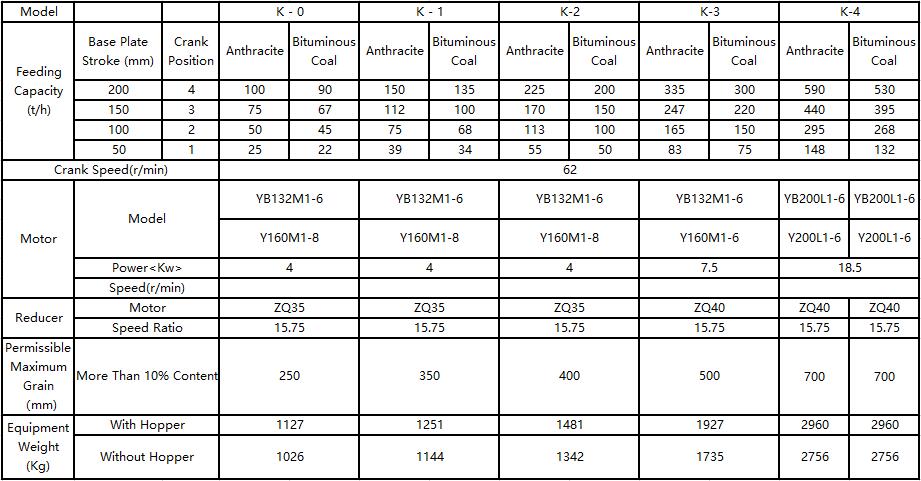

Technical parameter:

Leading Manufacturer for Mining Vibrating Screen - K type reciprocating feeder (coal feeder) – Jinte Related Video: