New Arrival China Magnetic Feeder - JDG-type Vibrating Grizzly Screen Feeder – Jinte

Belt Feeder for Coal

Features & Advantages

Technical Parameters:

|

Model |

Voltage(V) |

Transport Capacity (t/h) |

Maximum Feeding Granularity(mm) |

Power(Kw) |

|

JDG12040 |

380 |

240-400 |

350 |

7.5 |

|

JDG12050 |

380 |

35-600 |

350 |

11 |

|

JDG14040 |

380 |

460-800 |

350 |

15 |

|

JDG14050 |

380 |

560-1000 |

350 |

15 |

|

JDG14063 |

380 |

680-1200 |

350 |

18.5 |

Structure

Working principle

Structure

This vibrating feeder is mainly composed of driving device, coupling, bar and bar gate, chute, head funnel, frame, retaining roller, supporting roller, head sweeper, driving roller, reversing roller, tensioning device, etc.

Working principle

The material in the bin enters the chute through the connecting section and the sluice gate and falls onto the rubber belt. When the rubber belt is stationary, the material stops moving by the internal friction. When the driving drum starts to rotate under the drive of external force, it drives the rubber belt to move, and the rubber belt drives the material guiding funnel and outlet on it, and the material is discharged from the outlet continuously to complete the feeding process. The un-cleaned material bonded to the tape is scraped into the head funnel by the head sweeper.

Factory & Team

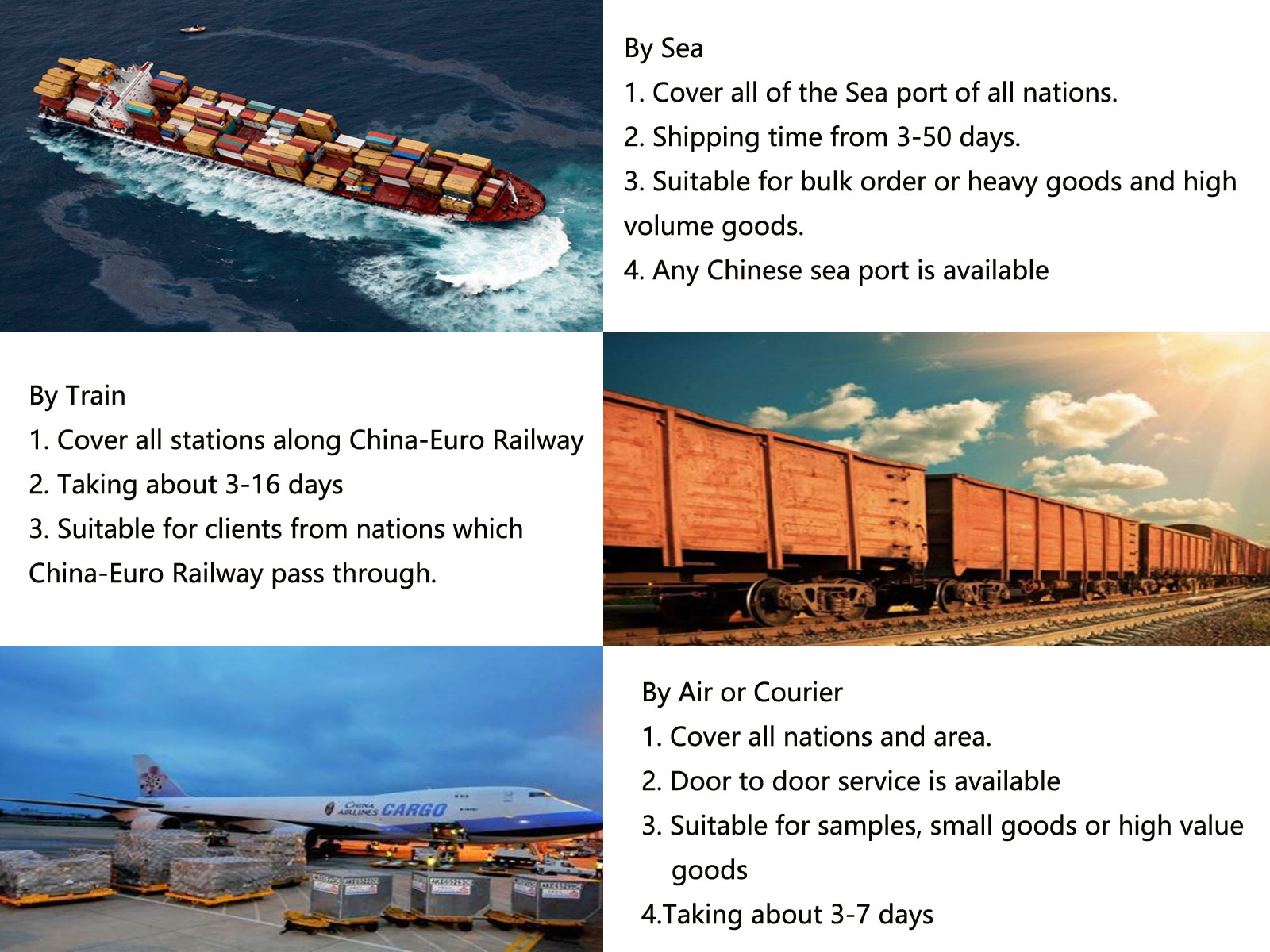

Delivery

New Arrival China Magnetic Feeder - JDG-type Vibrating Grizzly Screen Feeder – Jinte Related Video: