PriceList for Mini Vibrating Feeder - bar screen – Jinte

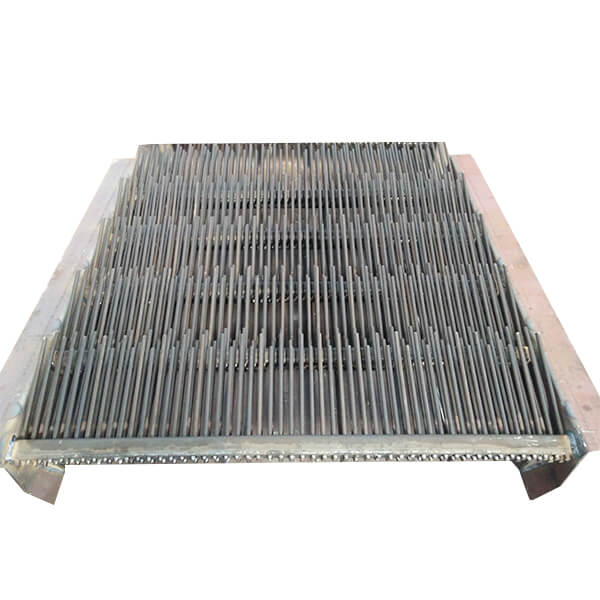

Intruduction:

Article rod sieve plate of high frequency tuning fork, while with sieve plate vibration, produce secondary high frequency resonance, make the material move faster, accelerated the sinking of sieve particles on the surface of the material and small particles have touch screen surface materials to mesh transverse speed, thereby increasing the probability of through the screen mesh, opening up to 80% of the sieve plate, have certain moisture sticky material, by the high frequency vibration shake, bonding caused jams in bar is not easily, is sticky or difficult to screen material containing fiber content, the most ideal sieve plate.

All kinds of size and screen hole size of new structure model sieve plate, especially for impact strength, hardness, wear resistance of high requirements. Wear-resistant screen plate is for fine screening in iron ore, raw coal classification, gold, building materials, and sand and stone screening in hydropower and nuclear power projects.

Applications:

1. metallurgy (iron ore, limestone, fluorite, cooling blast furnace slag, coke and other raw materials)

2. coke

3. coal

4. washing coal

5. chemical industry

6. building materials

7. hydropower projects

8. abrasive waste treatment

9. quarry

10. other industries of materials washing, screening, grading and other industries.

Advantages of bar sieve plate:

1, cantilever structure, plus bar sieve plate parts of the material performance, so this sieve plate has a high efficiency.

2. Single-layer and double-sided self-cleaning bar sieve plate can ensure that particles less than 5mm into the sinter are less than 5%.

3, to meet the increasingly high requirements of blast furnace feed.

4, Long service life.

PriceList for Mini Vibrating Feeder - bar screen – Jinte Related Video: